Geocell

Geocells are a type of geosynthetic material used in civil engineering and construction to stabilize soil, reinforce slopes, and improve load distribution. They are made from strips of polymeric material (often HDPE) that are connected to form a three-dimensional honeycomb structure. When these cells are filled with soil, gravel, or concrete, they create a stable, reinforced layer that can withstand significant loads and prevent erosion.

Structure of Geocells:

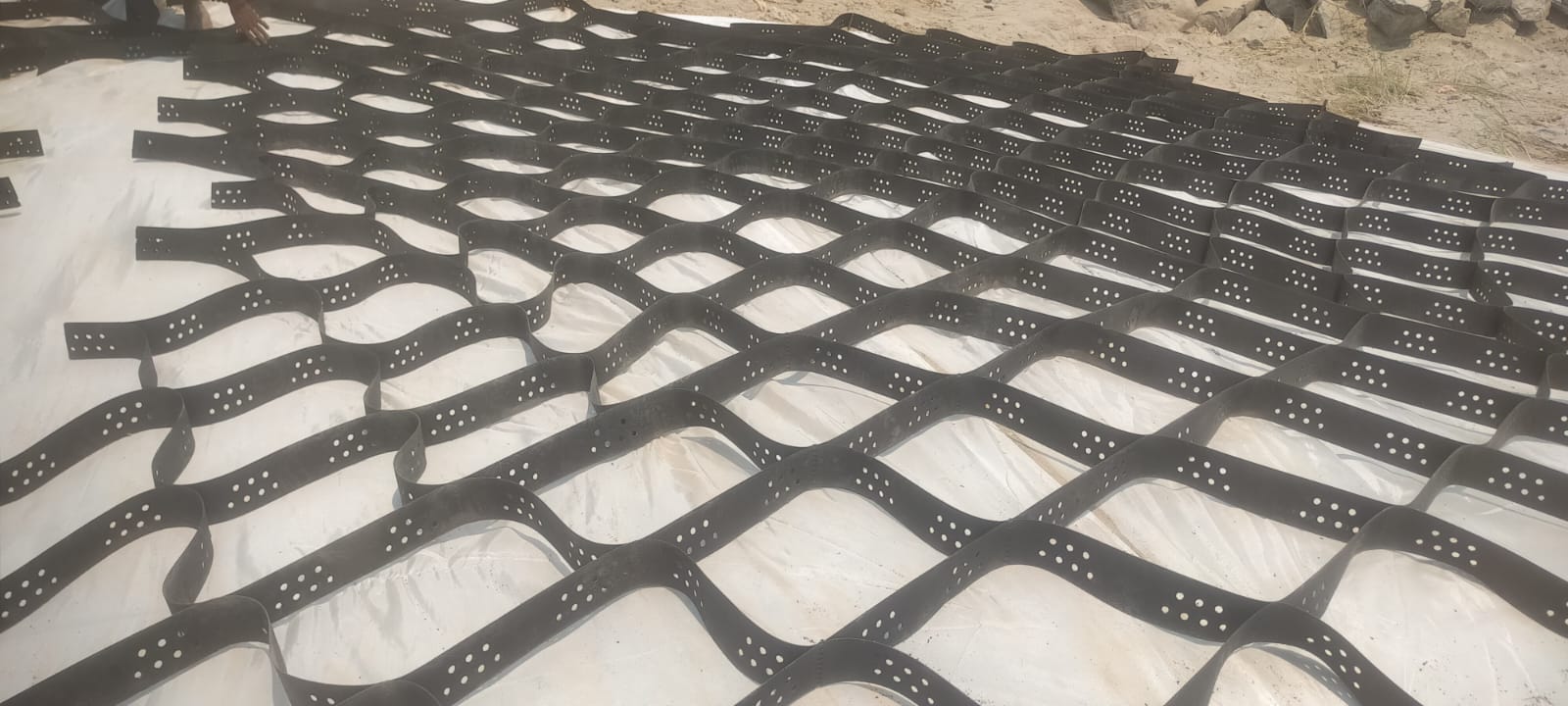

Polymeric Strips: The geocell is made up of interconnected strips of durable polymer material, typically high-density polyethylene (HDPE). These strips are ultrasonically welded at intervals, forming a honeycomb-like structure when expanded.

3D Honeycomb Structure: When the geocell is deployed, it expands into a flexible, three-dimensional grid of cells. This structure confines the fill material (soil, gravel, or concrete) within each cell, preventing lateral movement and improving stability.

Integration with Textiles:

Geocells can be used in combination with geotextiles to enhance their performance and expand their range of applications.

Geotextile Liner: A geotextile fabric is often placed underneath or around the geocell structure. This serves several purposes:

Separation: The geotextile prevents the mixing of different soil layers, maintaining the integrity of the fill material within the geocells.

Filtration: It allows water to pass through while preventing fine soil particles from washing out, thus reducing the risk of erosion and maintaining the stability of the structure.

Filtration: It allows water to pass through while preventing fine soil particles from washing out, thus reducing the risk of erosion and maintaining the stability of the structure.

Erosion Control: When used on slopes or embankments, geocells combined with geotextiles effectively prevent soil erosion. The geocell structure confines the soil, while the geotextile prevents the soil from being washed away by rain or surface runoff.Load Distribution: In road construction or load-bearing applications, the geotextile layer beneath the geocell helps distribute the load more evenly across the surface, reducing the stress on underlying soils and improving the overall performance of the structure.

Applications of Geocells with Textiles:

1)Slope and Embankment Stabilization: Geocells are commonly used to stabilize slopes and embankments, preventing landslides and erosion. The addition of a geotextile layer enhances the stability and longevity of these structures.

2)Retaining Walls: Geocells can be used to construct retaining walls, especially in areas with poor soil conditions. The geotextile layer helps prevent soil erosion behind the wall, improving its effectiveness.

3)Road Construction: Geocells are used to reinforce the base of roads and highways, particularly on soft or unstable soils. The geotextile layer improves load distribution and prevents the roadbed from sinking or deforming over time.

4)Green Roofs: In green roof applications, geocells combined with geotextiles are used to manage water flow and support vegetation. The geocell structure provides a stable growing medium, while the geotextile layer ensures proper drainage and prevents soil erosion.

Benefits of Geocells with Textiles:

1)Enhanced Stability: The combination of geocells and geotextiles provides superior soil stabilization, reducing the risk of erosion, landslides, and other ground failures.

2)Improved Load-Bearing Capacity: Geocells distribute loads more evenly, reducing stress on the soil and preventing deformation in roads and other load-bearing structures.

3)Versatility: Geocells can be used in a wide range of applications, from slope stabilization to road construction, and the addition of geotextiles expands their utility even further.

4)Cost-Effective: The use of geocells and geotextiles reduces the need for extensive earthworks and maintenance, lowering overall project costs.

Geocells combined with geotextiles are an effective and versatile solution for various engineering challenges, offering enhanced stability, durability, and environmental benefits across multiple applications.